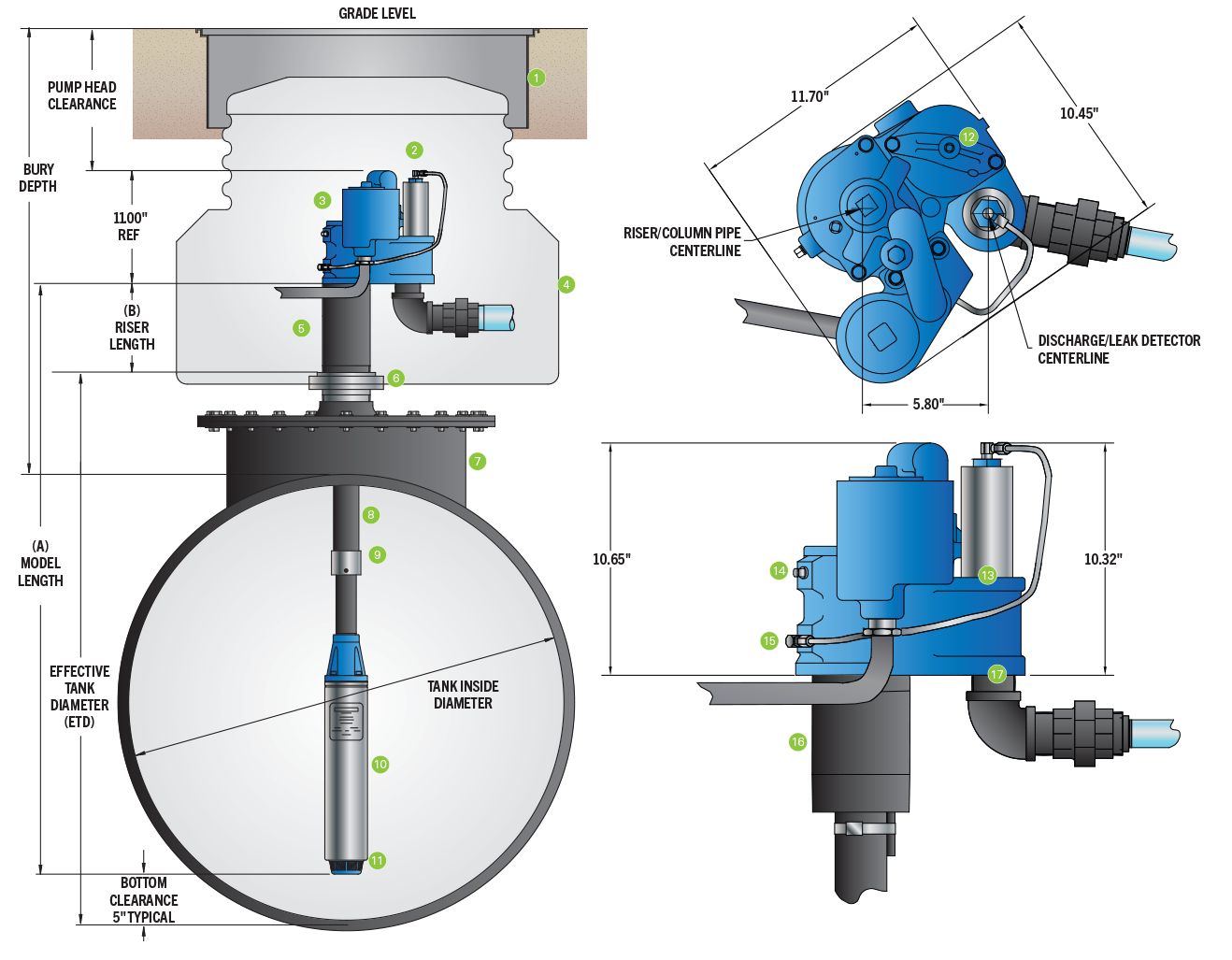

Turbine Pumb Interface

Turbine Pump Interface is a powerful tool that creates a network between your FE PETRO® STP controllers and EVO™ Series ATGs. Through TPI, the tank gauge can be programmed to respond to faults in the submersible pumping system and react with intelligence that pump controllers alone cannot.

Pump In Water Automation

When the water level in a tank approaches the pump intake, the tank gauge will enter alarm

mode and automatically shut down the pump, protecting the system and customer vehicles.